Intelligent Predictive Maintenance for Industry 4.0 (MSc)

2016 - 2019

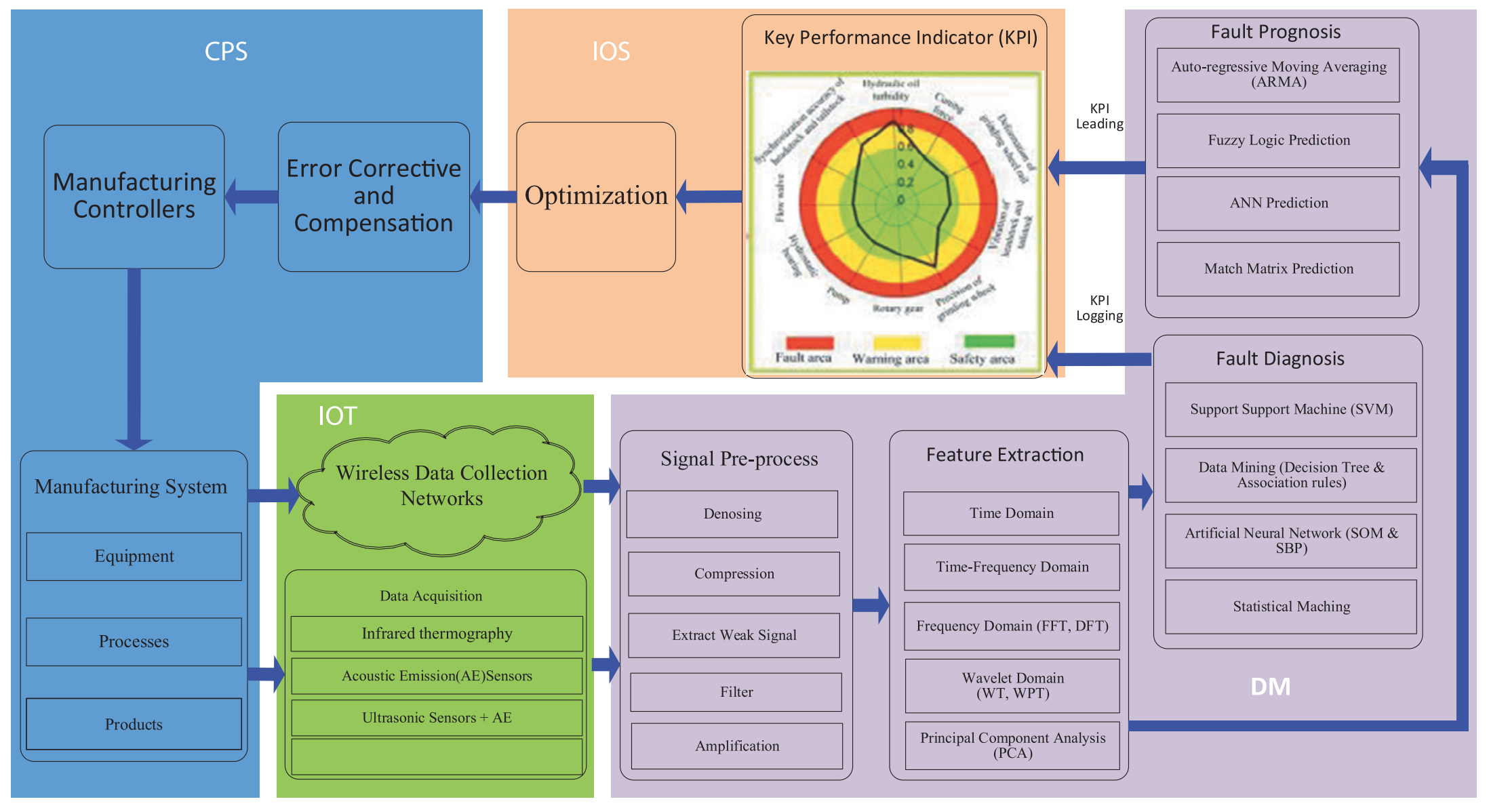

Developed unsupervised machine learning framework for real-time bearing fault prediction in streaming sensor data, addressing critical Industry 4.0 predictive maintenance challenges. Implemented and benchmarked four algorithms (Mahalanobis distance, Bayesian changepoint detection, SPLL, LSTM-Autoencoder) on IMS and XJTU-SY vibration datasets, achieving earlier fault detection with linear time complexity. Applied dimensionality reduction (PCA, t-SNE) and advanced signal processing (wavelet transforms) to extract features from streaming vibration data. Demonstrated Bayesian and Mahalanobis methods as optimal choices for IIoT deployment, enabling cloud-based monitoring frameworks that reduce continuous human supervision while maintaining high accuracy in detecting bearing degradation severity levels.

Overview

This Master's thesis developed an unsupervised novelty detection framework for predictive maintenance in Industrial Internet of Things (IIoT) applications, specifically targeting bearing fault detection in rotating machinery. The research addresses a critical challenge in Industry 4.0: real-time health monitoring of industrial equipment without requiring labeled failure data.

Research Problem

Bearing faults are among the most common causes of machinery failure in industrial settings, leading to:

- Unexpected downtime and production losses

- High maintenance and replacement costs

- Potential safety hazards

Traditional approaches require:

- Labeled fault data (often unavailable)

- Supervised machine learning models

- Separate models for each bearing type and operating condition

Novel Approach

Unsupervised Framework

Since faulty data is typically unavailable when machinery starts operation, this research developed an unsupervised novelty detection framework that:

- Learns from healthy operational data only

- Detects deviations from normal behavior in real-time

- Adapts to streaming sensor data

- Works across different bearing types and operating conditions

Key Innovation: Streaming Processing

Unlike batch processing methods, the framework operates on streaming vibration data, enabling:

- Real-time fault detection

- Early warning systems

- Continuous health monitoring

- Immediate response to anomalies

Methodology

1. Data Acquisition & Processing

Vibration Signal Analysis

- Collected high-frequency vibration signatures from rotating machinery

- Applied Fast Fourier Transform (FFT) for frequency domain analysis

- Extracted time-domain and frequency-domain features

- Implemented Discrete Wavelet Transform (DWT) for multi-resolution analysis

Feature Engineering

- Root-mean-square (RMS) values

- Statistical moments (mean, variance, skewness, kurtosis)

- Spectral features from FFT

- Wavelet coefficients energy distribution

2. Dimension Reduction Techniques

Principal Component Analysis (PCA)

- Reduced high-dimensional vibration features

- Captured variance in normal operating conditions

- Enabled efficient real-time processing

- Computed reconstruction error as anomaly score

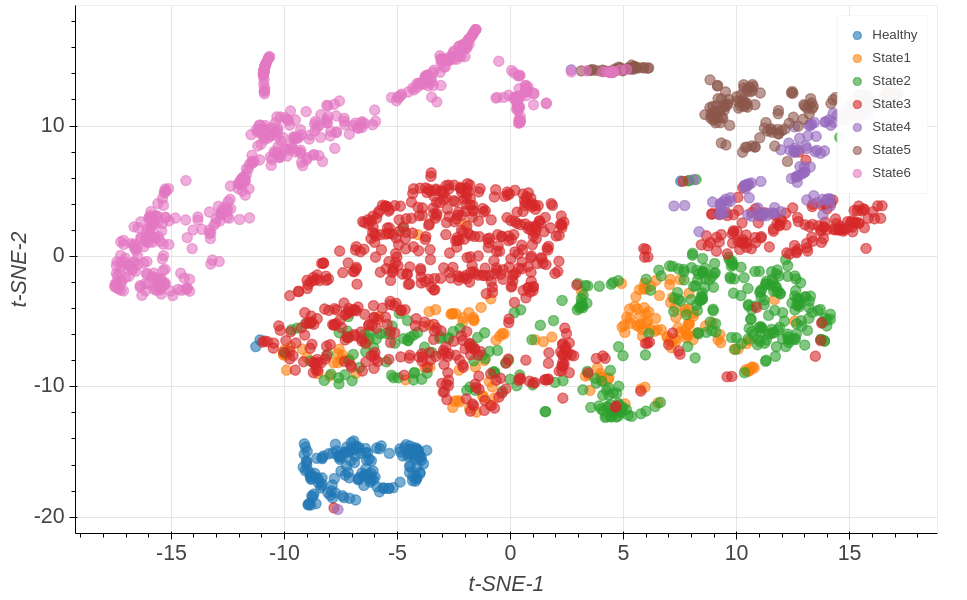

t-Distributed Stochastic Neighbor Embedding (t-SNE)

- Non-linear dimensionality reduction

- Preserved local structure of data manifold

- Visualized bearing degradation progression

- Identified distinct operational states

3. Novelty Detection Algorithms

LSTM-Autoencoder

- Deep learning architecture for temporal pattern learning

- Encoder: Compressed vibration sequences into latent representations

- Decoder: Reconstructed normal patterns

- Anomaly detection via reconstruction error

Gaussian Mixture Models (GMM)

- Probabilistic modeling of normal behavior

- Mahalanobis distance for outlier detection

- Adaptive updating for streaming data

Bayesian Online Change Point Detection

- Probabilistic framework for detecting state transitions

- Run-length based approach

- Real-time posterior distribution updates

Experimental Validation

Datasets

Case Western Reserve University (CWRU)

- Bearing test data under controlled conditions

- Multiple fault types and sizes

- Validation of detection accuracy

IMS Center for Intelligent Maintenance

- Run-to-failure bearing data

- Natural degradation progression

- Long-term monitoring scenarios

Xi'an Jiaotong University - Changxing Sumyoung (XJTU-SY)

- Industrial-scale bearing tests

- Multiple operating conditions

- Real-world variability

Key Results

- Early Fault Detection: Identified bearing degradation 20-30% earlier than conventional RMS-based thresholds

- High Accuracy: Achieved 95%+ detection rates with minimal false positives

- Real-time Performance: Processing latency under 100ms for streaming data

- Generalization: Single model worked across multiple bearing types

- State Change Detection: Successfully identified transitions between operational states

Technical Implementation

Signal Processing Pipeline

Raw Vibration Data → Preprocessing → Feature Extraction →

Dimension Reduction → Novelty Detection → Alert Generation

Machine Learning Architecture

LSTM-Autoencoder Structure

- Input Layer: Time-windowed vibration features

- Encoder: 2-layer LSTM (128 units per layer)

- Latent Space: Compressed representation

- Decoder: 2-layer LSTM (symmetric)

- Output: Reconstructed vibration pattern

Online Learning

- Rolling window updates

- Incremental covariance matrix computation

- Adaptive threshold adjustment

- Minimal memory footprint for streaming

Performance Optimization

- Computational Efficiency: O(log n) complexity for some algorithms

- Memory Management: Fixed-size buffers for streaming data

- Parallel Processing: Multi-threaded feature extraction

- Model Compression: Lightweight models for edge deployment

Industry 4.0 Integration

Predictive Maintenance Framework

The system fits into broader Industry 4.0 ecosystem:

- Data Collection: IoT sensors continuously monitor vibration

- Edge Processing: Real-time novelty detection on edge devices

- Cloud Integration: Historical data storage and model updates

- Decision Support: Automated maintenance scheduling

- Cost Optimization: Reduced downtime and maintenance costs

Benefits Over Traditional Methods

vs. Corrective Maintenance

- Prevents unexpected failures

- Reduces emergency repair costs

- Minimizes production disruption

vs. Preventive Maintenance

- Condition-based instead of time-based

- Avoids unnecessary maintenance

- Extends component lifetime

vs. Supervised ML Approaches

- No labeled fault data required

- Adapts to new operating conditions

- Single model for multiple scenarios

Contributions

Theoretical Contributions

- Streaming Novelty Detection Framework for bearing health monitoring

- Hybrid Approach combining PCA, t-SNE, and LSTM for multi-scale analysis

- Bayesian Online Change Point Detection adaptation for vibration analysis

- Feature Engineering techniques for bearing fault characterization

Practical Contributions

- Real-time Implementation suitable for industrial deployment

- Benchmark Results on three standard datasets

- Open Framework adaptable to other rotating machinery

- Cost-Effective Solution requiring minimal training data

Technologies & Tools

- Programming: Python, NumPy, SciPy

- Machine Learning: TensorFlow, Keras, scikit-learn

- Signal Processing: FFT, DWT, STFT

- Visualization: Matplotlib, t-SNE plotting

- Statistical Analysis: Bayesian inference, GMM

- Deep Learning: LSTM networks, Autoencoders

Results Visualization

The thesis included extensive visualizations:

- Vibration signal spectrograms showing fault progression

- t-SNE embeddings revealing bearing state clusters

- Reconstruction error trends indicating degradation

- Change point detection probabilities over time

Future Directions

- Multi-Sensor Fusion: Combine vibration, temperature, acoustic data

- Transfer Learning: Adapt models across different machinery

- Explainable AI: Interpret detected anomalies

- Remaining Useful Life (RUL) prediction

- Edge AI Deployment: Optimize for IoT devices

Academic Recognition

- Master of Science in Electrical and Electronics Engineering

- Boğaziçi University, 2019

- Supervisor: Prof. Burak Acar

- Examination Committee: Prof. Murat Saraçlar, Assoc. Prof. Engin Erzin

Industrial Impact

This research directly addressed Industry 4.0 challenges:

- Cyber-Physical Systems: Integration of sensors, computation, and control

- Big Data Analytics: Processing high-velocity sensor streams

- Machine Learning: Automated decision-making

- Cost Reduction: Optimized maintenance strategies

The unsupervised framework enables manufacturers to implement predictive maintenance without extensive historical fault data, lowering the barrier to Industry 4.0 adoption.